Sizes from 2 – 24 inch

Made in the UK

Products

We offer high quality products made in the UK

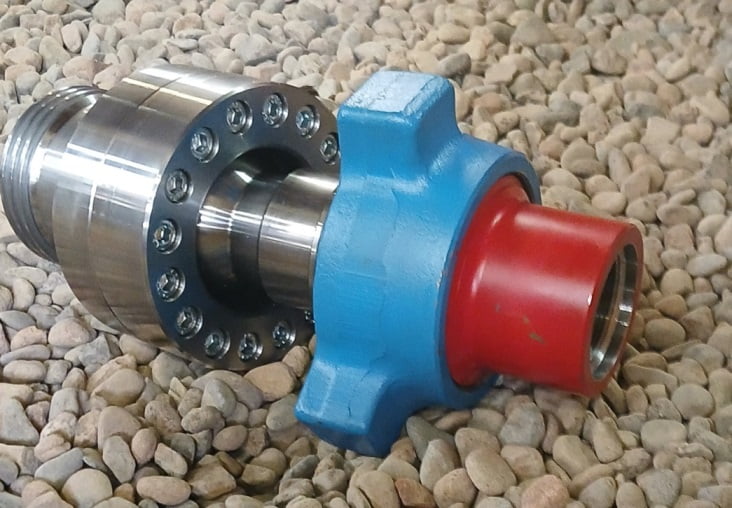

WECO Fittings

WECO Ball

Lug Unions

Flanges

Supermax Swagers

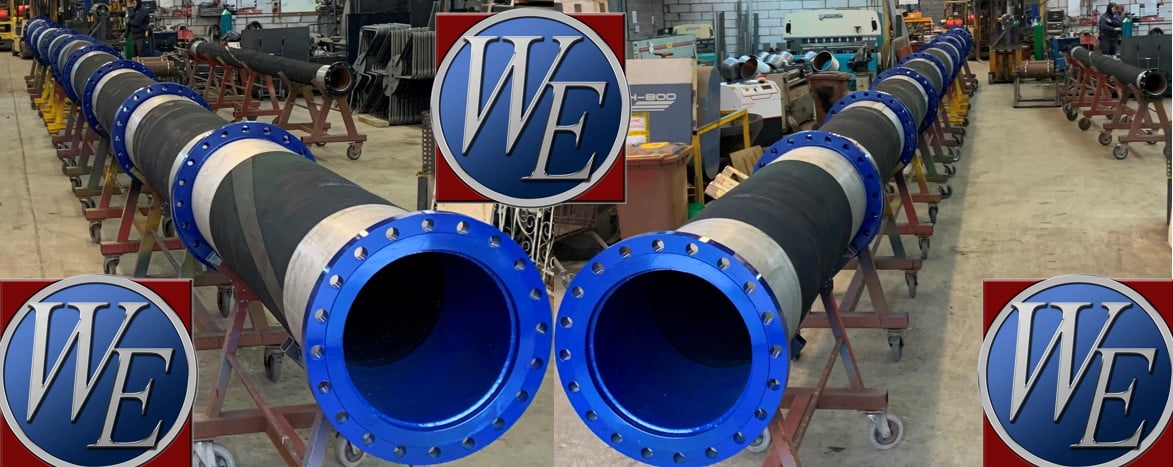

At Euro Hose Ltd, we are able to swage rubber hoses up to 24 inches, with a fast turnaround.

From 2 inch to 24 inch

Euro Hose also incorporates fully operational machine and fabrication workshops, using the latest CNC lathes, milling machines and welding equipment, which enable us to manufacture ninety percent of all fittings.

Euro Hose also carry an extensive stock of tube, flanges, formed elbows, tees, and Bauer type connections as unfinished goods in aluminium, carbon steel, duplex/super duplex and stainless steel, enabling us to create pipe adaptors to suit your individual application requirements.

Ready to Start Writing?

Resevoir Hoses

We are able to supply varies hoses for the water industry